At the current time, operating coal fired boilers with the lowest possible emissions of Nitrous Oxides are imperative. Proper sizing of coal transported through the burner lines is mandatory to achieve low NOx formation without unacceptable levels of unburned carbon in flyash.

At the current time, operating coal fired boilers with the lowest possible emissions of Nitrous Oxides are imperative. Proper sizing of coal transported through the burner lines is mandatory to achieve low NOx formation without unacceptable levels of unburned carbon in flyash.

Fineness is a primary mechanism for controlling flyash and bottom ash L.O.I.; however, it is also required to enhance rapid de-volatilization of coal which is required to reduce NOx. Low NOx is facilitated through lower burner stoichiometry, less intense mixing of air and fuel at the burners, combustion staging or low excess air. All of these factors provide less abundance of O2 in close proximity to the coal; making complete combustion of “char” carbon more difficult. Due to this, previous fineness standards which were typically 70% passing 200 Mesh and <1% remaining on 50 Mesh must be increased to higher levels to compensate for less intense combustion associated with Low NOx firing. Without increased coal fineness standards, NOx and LOI goals cannot be achieved as NOx and flyash L.O.I. are typically inversely related. That is, as NOx emissions decrease, flyash L.O.I. will increase.

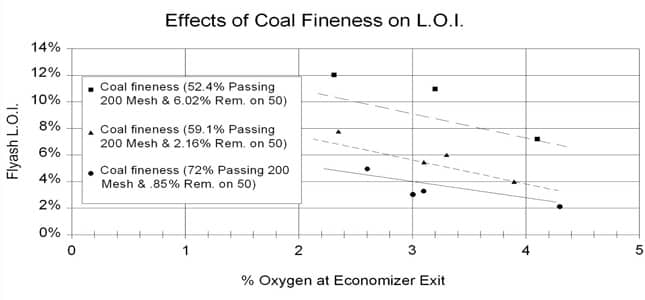

Higher than desired flyash or bottom ash Loss on Ignition (LOI) or unburned Carbon content is frequently caused by less than optimum coal fineness. The graph below illustrates a typical relationship between flyash LOI and coal fineness on a tangentially fired boiler firing Eastern Bituminous coal. Change in flyash LOI is less dramatic on Western coals due to the coal’s reactivity and ash content but this relationship still holds true.

These results will vary between different units due to furnace geometry (mainly furnace retention time), coal properties and firing configuration. Despite these differences, flyash L.O.I. will always be lower with higher fineness levels. Smaller coal particles require less time to burn, minimizing the chance of quenching carbonaceous deposits below their ignition point before leaving the furnace.